Geogrid in Different Materials and Types

Geogrid is a type of ground stabilization and subgrade reinforcement mesh, which is widely used in the roadways, highways, railways and slops construction. Using geogrid, the foundation will be solid and durable.

Material of geogrid

The geogrid is commonly made of polypropylene or high density polyethylene, which are UV stabilized, chemical and biological resistance. Additional, we can also supply the steel plastic, fiberglass and polyester material geogrid.

GEO-02: Fiberglass geogrid.

GEO-03: Polyester geogrid.

GEO-04: Steel plastic geogrid.

The geogrid is extruded into sheet and then punched into a continuous mesh pattern and finally stretched. The geogrid can be stretched into different directions, so it can be divided into uniaxial plastic geogrid, biaxial plastic geogrid, triaxial geogrid and quaxial geogrid.

Uniaxial plastic geogrid. The uniaxial plastic geogrid refers to the geogrid which is stretched in the transverse direction. It will form a long rectangular mesh pattern. The uniaxial plastic geogrid forms a compact interlock system and has good flexural stiffness and high strength. The uniaxial plastic geogrid is cheaper than the other types of geogrid, it is suitable for the tight budget engineering and geotechnical projects.

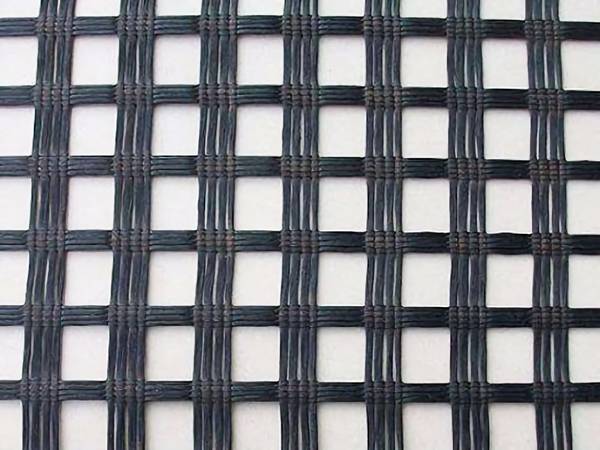

Biaxial plastic geogrid. Biaxial plastic geogrid is made of polypropylene. Compared with uniaxial plastic geogrid, which is stretched in transverse directions, the biaxial plastic geogrid is stretched in both transverse direction and longitudinal direction. Biaxial plastic geogrid forms a series of square mesh pattern. The biaxial plastic geogrid has better strength than the uniaxial plastic geogrid. It can be used in the slop and mine tunnel constructions.

GEO-05: Uniaxial geogrid with transverse direction stretches.

GEO-06: Biaxial geogrid with transverse and longitudinal direction stretches.

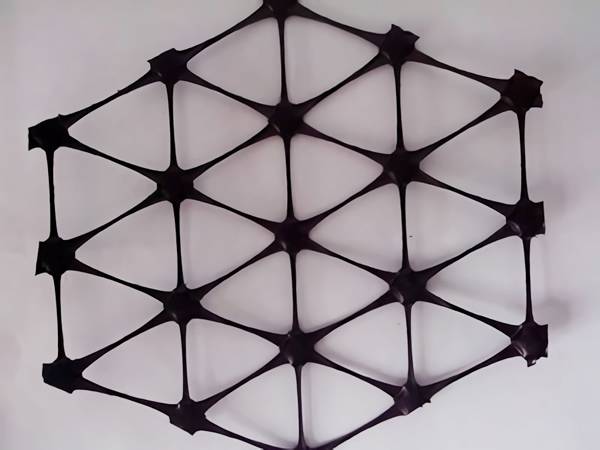

Triaxial plastic geogrid. As we all know, the triangle is the most durable structure. The triaxial plastic geogrid is stretched in equilateral direction to form triangular structure. Several triangle meshes creates the triaxial plastic geogrid and makes the geogrid a higher tensile strength than the uniaxial and biaxial plastic geogrid. It is widely used in the high bearing capacity traffic areas.

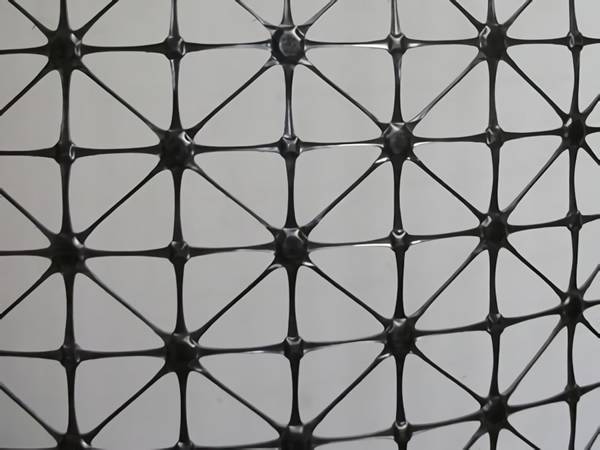

Quaxial plastic geogrid. It is the most stable and durable structure among all types of geogrid. Made of polypropylene, the quaxial plastic geogrid is UV stabilized and chemical, biological resistance. The longitudinal, transverse and 45 degree directions stretches supplies highest tensile strength for the geogrid.

GEO-07: Trial plastic geogrid with equilateral direction stretches.

GEO-08: Quaxial plastic geogrid has longitudinal, transverse and 45 degree direction stretches.

Applications of geogrid

- Geogrid is mainly used in the foundation construction of roadway, highway, railway and other roadbed constructions.

- It can be used on the slope to prevent soil from flowing down to the road.

- It can be used in the mine tunnel constructions for reinforcement.

GEO-09: Plastic geogrid for roadway reinforcement.

GEO-10: Plastic geogrid is used in the railway foundation construction.

GEO-11: Plastic geogrid for mine reinforcement.

GEO-12: Geogrid can be used in the slope to prevent soil falling down.

PP uniaxial plastic geogrid technical sheet

| Item |

PPUG50 |

PPUG60 |

PPUG80 |

PPUG110 |

PPUG150 |

PPUG200 |

PPUG260 |

| Material |

Polypropylene (PP) |

| Yield Tensile Strength ≥ (KN/m) |

50 |

60 |

80 |

110 |

150 |

200 |

260 |

| Tensile Strength in 2%Strain ≥ (KN/m) |

12 |

17 |

26 |

32 |

62 |

85 |

94 |

| Tensile Strength in 5%Strain ≥ (KN/m) |

28 |

35 |

48 |

64 |

110 |

145 |

185 |

| Strain Yield Tensile Strength ≤ (%) |

10 |

| Roll Length (m) |

100 |

50 |

| Roll Width (m) |

1-3 |

HDPE uniaxial plastic geogrid technical sheet

| Item |

PEUG35 |

PEUG60 |

PEUG80 |

PEUG120 |

PEUG150 |

PEUG160 |

PEUG200 |

| Material |

High Density Polyethylene (HDPE) |

| Carbon Black ≥ (%) |

2 |

| Yield Tensile Strength ≥ (KN/M) |

35 |

60 |

80 |

120 |

150 |

160 |

200 |

| Tensile Strength in 2% Strain ≥ (KN/M) |

9 |

16 |

23 |

35 |

45 |

47 |

58 |

| Tensile Strength in 5% Strain ≥ (KN/M) |

18 |

31 |

44 |

65 |

92 |

93 |

115 |

| Strain Yield Tensile Strength ≤ (%) |

12 |

| Roll Length (m) |

75 |

30 |

| Roll Width (m) |

1 or 2 |

Biaxial plastic geogrid technical sheet

| Item |

BPG-15 |

BPG-20 |

BPG-30 |

BPG-40 |

BPG-45 |

| Material |

Polypropylene (PP) |

| Minimum Carbon Black ≥ (%) |

2 |

| Tensile Strength in 2% Strain ≥ (KN/M) |

MD |

5 |

7 |

10.5 |

14 |

16 |

| CMD |

5 |

7 |

10.5 |

14 |

16 |

| Tensile Strength in 5% Strain ≥ (KN/M) |

MD |

7 |

14 |

21 |

28 |

32 |

| CMD |

7 |

14 |

21 |

28 |

32 |

| Yield Tensile Strength ≥ (KN/M) |

MD |

15 |

20 |

30 |

40 |

45 |

| CMD |

15 |

20 |

30 |

40 |

45 |

| Strain Yield Strain ≤ (%) |

MD |

13 |

13 |

13 |

13 |

13 |

| CMD |

13 |

13 |

13 |

13 |

13 |

| Dimensions |

Roll Width (m) |

3.95 |

3.95 |

3.95 |

3.95 |

3.95 |

| Roll Length (m) |

50 |

50 |

50 |

50 |

50 |

| Roll Weight (kg) |

38 |

50 |

68 |

96 |

110 |

Quaxial plastic geogrid technical sheet

| Quaxial plastic geogrid technical sheet |

| Index Properties |

Unit |

MD Values |

+45℃ Values |

-45℃ Values |

th Values |

| Polymer |

- |

PP |

- |

- |

PP |

| Tensile Strength in 2% Strain |

KN/M |

2.3 |

1.6 |

1.6 |

2.3 |

| Secant Modulus in 2% Strain |

KN/M |

115 |

80 |

80 |

115 |

| Tensile Strength in 5% Strain |

KN/M |

5.3 |

3.7 |

3.7 |

5.3 |

| Secant Modulus in 5% Strain |

KN/M |

106 |

74 |

74 |

106 |

| Strain Ultimate Strength |

% |

13 |

13 |

13 |

13 |

| Secant Stiffness in 0.5% Strain |

KN/M |

280 |

- |

- |

- |

| QPG-170 technical specifications |

| Index Properties |

Unit |

MD Values |

+45℃ Values |

-45℃ Values |

th Values |

| Polymer |

- |

PP |

- |

- |

PP |

| Tensile Strength in 2% Strain |

KN/M |

3.4 |

2.4 |

2.4 |

3.4 |

| Secant Modulus in 2% Strain |

KN/M |

170 |

120 |

120 |

170 |

| Tensile Strength in 5% Strain |

KN/M |

8.0 |

5.6 |

5.6 |

8.0 |

| Secant Modulus in 5% Strain |

KN/M |

160 |

112 |

112 |

160 |

| Strain Ultimate Strength |

% |

13 |

13 |

13 |

13 |

| Secant Stiffness in 0.5% Strain |

KN/M |

480 |

- |

- |

- |

| QPG-230 technical specifications |

| Index Properties |

Unit |

MD Values |

+45℃ Values |

-45℃ Values |

th Values |

| Polymer |

- |

PP |

- |

- |

PP |

| Tensile Strength in 2% Strain |

KN/M |

4.6 |

3.2 |

3.2 |

4.6 |

| Secant Modulus in 2% Strain |

KN/M |

230 |

160 |

160 |

230 |

| Tensile Strength in 5% Strain |

KN/M |

10.6 |

7.4 |

7.4 |

10.6 |

| Secant Modulus in 5% Strain |

KN/M |

210 |

148 |

148 |

210 |

| Strain Ultimate Strength |

% |

13 |

13 |

13 |

13 |

| Secant Stiffness in 0.5% Strain |

KN/M |

530 |

- |

- |

- |